Wallys 74 project

+21

Limey SE

dynchel

ecuto74

knightfan26917

77mali

ant7377

pila

michiganlarry

driveit

thatfnthing

toms74laguna

dragons_lair59

WyldeBill66

G3NUT

Joe73

Landonus

1973 454 MONTE

Hawk03

Brainstain

1973montec

BicknellWelding

25 posters

G3GM :: Media :: G3 Project Pictures

Page 2 of 5

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Wallys 74 project

Re: Wallys 74 project

Don't you just love seeing this. A snapped off exhaust bolt in a Aluminum head.

[img] [/img]

[/img]

Then I snapped a easy out off in it. So I Figured I'd try and weld a nut on the snapped stud and easy out then unscrew it. It took 5 nuts to get it all the way out, as they would spin off and break weld. I found you need to let it cool completely before trying to spin it out with the aluminum head.

[img] [/img]

[/img]

[img]

[/img]

[/img]Then I snapped a easy out off in it. So I Figured I'd try and weld a nut on the snapped stud and easy out then unscrew it. It took 5 nuts to get it all the way out, as they would spin off and break weld. I found you need to let it cool completely before trying to spin it out with the aluminum head.

[img]

[/img]

[/img]

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Here is my first post of a video ever.

Its the snapped off easy out and bolt coming out.

Its the snapped off easy out and bolt coming out.

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

I agree that you have to let everything completely cool before attempting to remove the broken bolt. But before I attempt the removal, I like to use a propane torch and heat the aluminum part a little. Aluminum dissipates heat quickly but still expands a little. Just to take a little pressure off the threads.

Joe73- Donating Member

- Street Cred : 83

Re: Wallys 74 project

Re: Wallys 74 project

Getting some more stuff done. I'm waiting on parts right now. I just sent out the wire harness and Ecm to WWW.LSX-HARNESS.COM. He said about two weeks I should have it back. Ordered Hooker cast iron headers http://www.holley.com/Application/LS They will be here tomorrow. I have drive shaft in X-member installed, Just about ready to install Radiator with dual electric fans. I need to get exhaust done before I can run trany lines. Then hook up Fuel lines after flushing out tank. Install harness and hope she fires up.

So yes I'm getting there. Just has been tight for funds lately. I took in y change can and had 752.00 in change so that helped out to get some new parts. Got to love it when we start digging for change to keep the project alive.

My brother is supposed to be bringing his 58 Pontiac chieftain over for some body work and paint but he is behind so that's helping me get more done. when his car comes mine goes out side.

So yes I'm getting there. Just has been tight for funds lately. I took in y change can and had 752.00 in change so that helped out to get some new parts. Got to love it when we start digging for change to keep the project alive.

My brother is supposed to be bringing his 58 Pontiac chieftain over for some body work and paint but he is behind so that's helping me get more done. when his car comes mine goes out side.

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Here is some more photos of the progress.

Summit oil pan

Summit oil pan

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Glad to hear your making progress. the person doing your harness does good work. when you get it back everything will be labeled. i was going to order shorty headers for mine but i'm still on the fence. when you get the manifolds could please post a pic of them installed on your engine. if they fit good maybe i will bite the bullet and order those also. i hear ya on the tight funds i'm in the same boat. i have to pick and choose what i really need opposed to what i want.

G3NUT- Donating Member

- Street Cred : 11

Re: Wallys 74 project

Re: Wallys 74 project

Made some more progress and getting closer to firing up. I got exhaust maniflds on and did my own exhaust. [url=

[url=[url=https://servimg.com/view/17248508/147]

[url=[url=https://servimg.com/view/17248508/148]

[url=[url=https://servimg.com/view/17248508/149]

Have tranny lines ran, raidator installed, All hoses hooked up.

[url=[url=https://servimg.com/view/17248508/150]

Moved on to testing fuel pump. The car came with the 95 impala fuel tank mounted in. Hooked up pump to test it and nothing. Dropped tank to find it had 17 gallons of fuel sitting from 1998. Man that stuff smells horrible. The good thing is it is a plastic fuel tank so i can clean it out my self. Ordered new sending unit and fuel pump today.

Just waiting for harness to come back and hook up shifter and add fluids. A few odds and ends and can't wait it here it run.[

Here is the fuel tank

url=[url=https://servimg.com/view/17248508/151]

Here is a white pail with the fuel in it.

[url=[url=https://servimg.com/view/17248508/152]

Here is the rusted out sending unit.

[url=[url=https://servimg.com/view/17248508/153]

[url=[url=https://servimg.com/view/17248508/147]

[url=[url=https://servimg.com/view/17248508/148]

[url=[url=https://servimg.com/view/17248508/149]

Have tranny lines ran, raidator installed, All hoses hooked up.

[url=[url=https://servimg.com/view/17248508/150]

Moved on to testing fuel pump. The car came with the 95 impala fuel tank mounted in. Hooked up pump to test it and nothing. Dropped tank to find it had 17 gallons of fuel sitting from 1998. Man that stuff smells horrible. The good thing is it is a plastic fuel tank so i can clean it out my self. Ordered new sending unit and fuel pump today.

Just waiting for harness to come back and hook up shifter and add fluids. A few odds and ends and can't wait it here it run.[

Here is the fuel tank

url=[url=https://servimg.com/view/17248508/151]

Here is a white pail with the fuel in it.

[url=[url=https://servimg.com/view/17248508/152]

Here is the rusted out sending unit.

[url=[url=https://servimg.com/view/17248508/153]

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Looking good

What coating on the exhaust mannyfolders?

What coating on the exhaust mannyfolders?

77mali- Donating Member

- Street Cred : 62

Re: Wallys 74 project

Re: Wallys 74 project

I have a can of Eastwood ceramic black that I have had for 15 years. Its just about empty now as it was only a pint can. The good part is you can touch them up if they start to show signs of wear from heat. I got it when I did my 56 Chevy as I have cast iron headers from sanders on that one. Each spring when I take it out of storage is when you see some lite surface rust. I drive it home to get a good heat cycle on them then let it cool and touch it up with a paint brush. They smoke for a bit after it warms up but I like it.

here is a link

http://www.eastwood.com/satin-black-high-temp-coating-kit.html

here is a link

http://www.eastwood.com/satin-black-high-temp-coating-kit.html

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

The consistency of the Eastwood coating in your pics looks very similar to what I have & looks like it will actually hold up. Mine were coated w/ a 1200* Por15 product after grinding off a spray-on VHT hi temp ceramic that I tried out. I don't think the VHT coating would have survived one season.

77mali- Donating Member

- Street Cred : 62

Re: Wallys 74 project

Re: Wallys 74 project

Don't feel too bad, the ceramic on my Malibu headers is showing some small pits, and they don't have much over 1000 miles on them. Stainless steel type like built for Camaros etc would likely hold up for a long time.

pila- Donating Member

- Street Cred : 43

Re: Wallys 74 project

Re: Wallys 74 project

Well the car is up and running. Had some issues with wire harness they had the speedo and fuel pump wires crossed so had a no start for a while was fun to to diagnose that one. Wires were to short to mount ECM inside so its going on fire wall now. don't have it all finished wired up yet just temp to get it running. I have not driven it just shifted through all 3 gears and reverse on stands. Now installing new stock type body harness. Was happy had no exhaust leaks or any leaks. Will be a bit before I can get back on it. Just dove into a kitchen remodel project. Cabinets are to be here April 13th so can get back on it after that. Al least it can move on its own now.

Here is a rough video of it running.

https://www.youtube.com/watch?v=S7X263R87Bg&feature=youtu.be

Here is a rough video of it running.

https://www.youtube.com/watch?v=S7X263R87Bg&feature=youtu.be

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Woohooo. Sounds awesome! That gives me incouragement. I am still a couple weeks from firing. What did you do for the radiator to sit on? Looks like the truck accessory drive fits in much nicer than the ls1. I ended up having to get Holley brackets to move the alternator and ac compressor.

Great work.

Great work.

michiganlarry- G3GM Member

- Street Cred : 1

Re: Wallys 74 project

Re: Wallys 74 project

I used the stock core support and top plate. The new Rad came with the car so I have no clue if its stock for the 74 or not. But it fit right in just like my 73 does. It sits on the same rubber pads on the bottom.

Still do not know if hood will clear with the shaker hood cut out, but i know a stock hood with no cut out will not clear. The car intake is way lower than the truck.

I may have to move that steam vent and return hose to throttle body as cold air intake tube i bought for a truck passes right through it.

Where does those Holly brackets relocate the accessories?

Still do not know if hood will clear with the shaker hood cut out, but i know a stock hood with no cut out will not clear. The car intake is way lower than the truck.

I may have to move that steam vent and return hose to throttle body as cold air intake tube i bought for a truck passes right through it.

Where does those Holly brackets relocate the accessories?

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

The brackets move them from down by the crank to about where yours are.

michiganlarry- G3GM Member

- Street Cred : 1

Re: Wallys 74 project

Re: Wallys 74 project

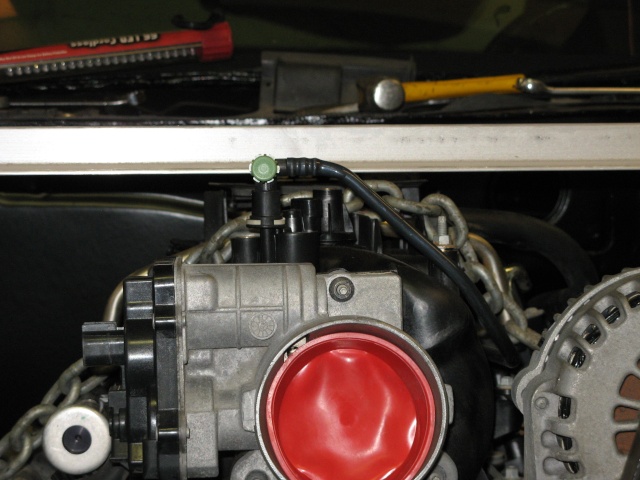

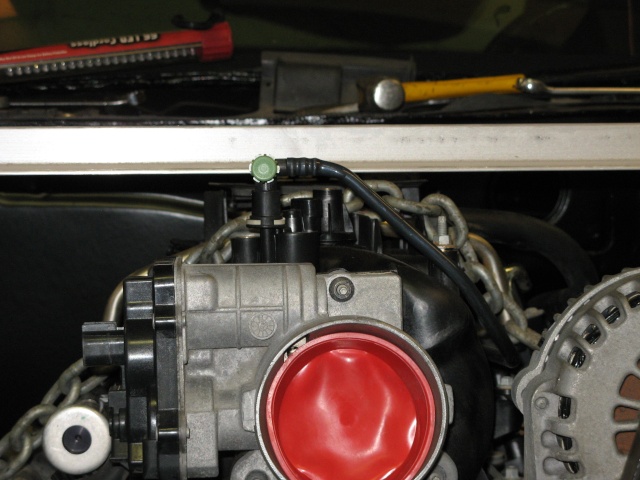

Here is a pic of my engine with the holley brackets

michiganlarry- G3GM Member

- Street Cred : 1

Re: Wallys 74 project

Re: Wallys 74 project

Have you put a straight edge across fenders to see if it will clear the hood.

Here is what I have for clearance and thats the top of the fenders so hood sits down in a 1or2

[url=[url=https://servimg.com/view/17248508/179]

[url=[url=https://servimg.com/view/17248508/180]

I'm told you can swap the intake from truck to car with the drive by cable throttle body but not the drive by wire as it will hit the upper rad hose nipple. I did read a post that one guy bent the outlet tube on the water pump to clear a drive by wire throttle body. Its not like the good old days of a short or long water pump. The blocks holes are interchangeable but not all the accessories.

Here is what I have for clearance and thats the top of the fenders so hood sits down in a 1or2

[url=[url=https://servimg.com/view/17248508/179]

[url=[url=https://servimg.com/view/17248508/180]

I'm told you can swap the intake from truck to car with the drive by cable throttle body but not the drive by wire as it will hit the upper rad hose nipple. I did read a post that one guy bent the outlet tube on the water pump to clear a drive by wire throttle body. Its not like the good old days of a short or long water pump. The blocks holes are interchangeable but not all the accessories.

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Man I sure hope it clears. LOL The front clip is sitting on the garage floor but it looks like is should. Guess I will know when I put the clip back on.

I think the car manifold is quite a bit lower than the truck one and to my eye the top of the alternator is about the same as the top of the manifold.

I think the car manifold is quite a bit lower than the truck one and to my eye the top of the alternator is about the same as the top of the manifold.

michiganlarry- G3GM Member

- Street Cred : 1

Re: Wallys 74 project

Re: Wallys 74 project

Yes it does look a lot lower that the truck setup.

I'm as low as I can get it. Maybe a 1/4 gap from pan to cross member and the pan still hangs below the cross member. Your pan fits better and the one I bought was listed for retrofit's. I got it from Summit racing. Came with new pick up tube and splash pan. I will be welding a skid type plate on bottom of cross member when I get it deliverable.

I'm as low as I can get it. Maybe a 1/4 gap from pan to cross member and the pan still hangs below the cross member. Your pan fits better and the one I bought was listed for retrofit's. I got it from Summit racing. Came with new pick up tube and splash pan. I will be welding a skid type plate on bottom of cross member when I get it deliverable.

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Here is a photo of the oil pan area.

[url=[url=https://servimg.com/view/17248508/181]

[url=[url=https://servimg.com/view/17248508/181]

Wallyuph- Donating Member

- Street Cred : 31

Re: Wallys 74 project

Re: Wallys 74 project

Yea I think you are going to want to protect that. Got me worried about the hood clearing on my son's car now.

michiganlarry- G3GM Member

- Street Cred : 1

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

G3GM :: Media :: G3 Project Pictures

Page 2 of 5

Permissions in this forum:

You cannot reply to topics in this forum|

|

|

» Roll Call and Car showcase

» Central Texas Noob

» Welcome Keith Seymore

» Wanted: Front park lamp assemblies

» 75 Hurst Olds T-tpos

» G3 Chevy rims- help ID these

» 75 el camino project.

» Have had a few questions

» vinyl top removal